MGEM: Turning Machine Data into Intelligent Manufacturing Decisions

Modern manufacturing runs on data, but too often, critical machine signals are underutilized, siloed, or only reviewed after something goes wrong. Machine-Generated Events Monitoring (MGEM) addresses this gap by transforming real-time Industrial IoT (IIoT) data into actionable intelligence that supports operational resilience, efficiency, and scale.

MGEM applies advanced analytics and machine learning (ML) to continuous event streams from sensors, equipment, and production systems, enabling manufacturers to anticipate issues, optimize processes, and make faster, more informed decisions across the plant floor and beyond.

Manufacturing Business Challenge

From Reactive Operations to Predictive Control in Manufacturing

Manufacturers today face mounting pressure to increase output, maintain quality, and reduce costs; all while operating in highly complex, interconnected environments. Unplanned downtime, process variability, and late detection of equipment issues directly impact margins, customer commitments, and long-term competitiveness.

Traditional monitoring approaches often provide visibility without foresight. They tell you what happened, not what’s about to happen. MGEM shifts this paradigm by enabling proactive, data-driven operations grounded in real-time insight.

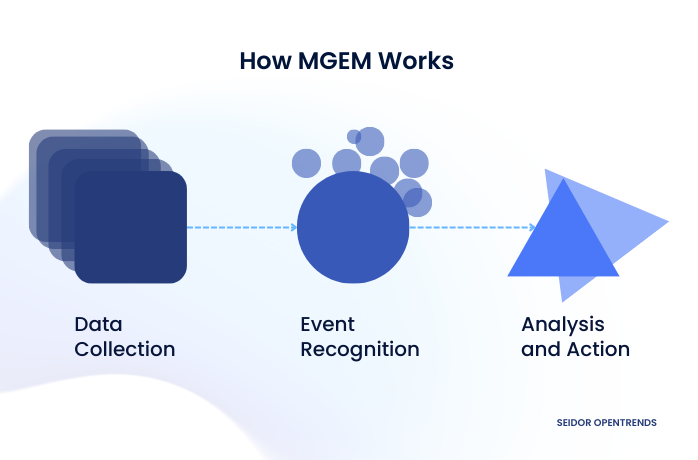

The MGEM Approach: Connecting Events to Outcomes

MGEM bridges the gap between raw IIoT sensor data and business-relevant insights. Using advanced analytics and unsupervised machine learning, MGEM continuously analyzes machine-generated events to:

- Detect anomalies and early warning signals

- Identify hidden patterns across processes and equipment

- Anticipate failures before they disrupt operations

Rather than relying solely on predefined thresholds, MGEM adapts to real operating conditions, learning from data as systems evolve.

Manufacturing Business Impact: What MGEM Delivers

Predictive Maintenance at Scale

By identifying subtle deviations in sensor data, MGEM enables maintenance teams to intervene before failures occur. This reduces unplanned downtime, extends asset life, and lowers overall maintenance costs.

For example, manufacturers can detect abnormal vibration patterns in critical pumps or temperature deviations in paint booths long before they trigger production stoppages.

Real-Time Quality Assurance

MGEM supports continuous quality monitoring across production lines, enabling early detection of deviations that lead to defects or scrap. The result is more consistent output, reduced rework, and improved yield, without slowing production.

Executive-Grade Decision Intelligence

MGEM consolidates operational signals into insights that support better decisions around scheduling, capacity planning, and resource allocation. Manufacturers gain a clearer, real-time understanding of plant performance, grounded in data, not assumptions.

Security by Design

As manufacturing environments become more connected, security becomes non-negotiable. MGEM architectures are designed with enterprise-grade security controls to protect sensitive operational data and ensure system integrity across connected assets.

MGEM Scalable by Design

MGEM Scalable From Single Line to Global Operations

MGEM solutions are built to scale, whether supporting a single production line or a global manufacturing network. The architecture adapts to varying data volumes, plant sizes, and operational complexity, ensuring insights remain consistent and reliable as operations grow.

Integration is often the biggest hurdle. Manufacturing environments typically span ERP systems, MES platforms, historians, and cloud services. MGEM can integrate directly with event streaming and data platforms such as AWS IoT Events, Azure Event Hubs, or Google Pub/Sub, and extend into enterprise analytics environments such as Snowflake, Datadog, or Splunk. IoT experts ensure machine events flow seamlessly into broader operational and analytical workflows.

Making MGEM Insights Actionable

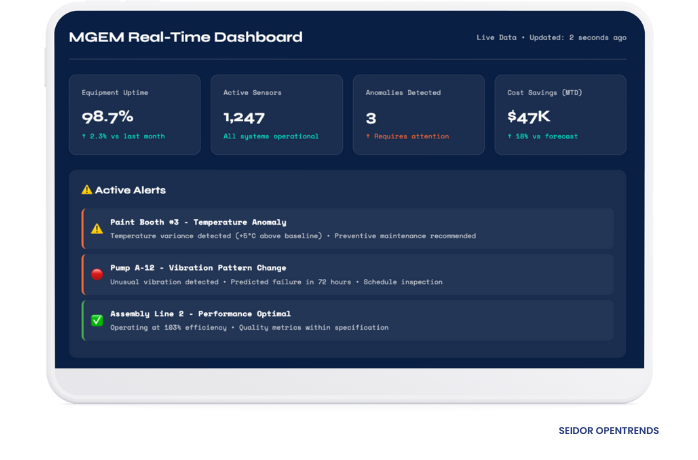

The Role of MGEM Visualization

Data alone doesn’t drive action, clarity does. Effective MGEM implementations prioritize intuitive dashboards and visualizations that surface what matters most. Imagine a centralized view of equipment health, with real-time status indicators and prioritized alerts that enable teams to act immediately rather than investigate endlessly.

For executives, this means faster situational awareness. For operators, it means clearer priorities. For the organization, it means better outcomes.

Getting Started with MGEM

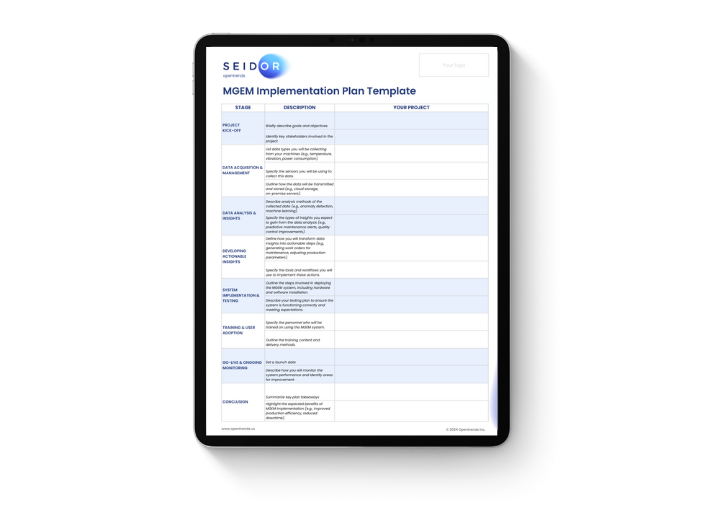

Design an event-driven intelligence layer that aligns with your operational goals, data landscape, and growth strategy. Download our MGEM Implementation Plan Template to explore a structured, step-by-step approach for your organization.

MGEM Beyond Manufacturing

While manufacturing is a natural fit, MGEM’s event-driven intelligence model applies equally to other asset-intensive industries, including transportation, energy, utilities, and facilities management. Wherever real-time operational insight is critical.

FAQs About Industrial IoT Monitoring and Predictive Maintenance

What is Machine-Generated Events Monitoring (MGEM) and how does it improve manufacturing operations?

MGEM (Machine-Generated Events Monitoring) is an Industrial IoT solution that analyzes real-time sensor data from connected devices to detect anomalies, uncover patterns, and predict equipment failures before they occur. By turning raw machine events into actionable insights, MGEM enhances predictive maintenance, reduces unplanned downtime, and drives data-informed decisions across production systems, helping manufacturers boost efficiency and competitiveness.

How does IoT-enabled predictive maintenance reduce downtime and maintenance costs?

IoT-enabled predictive maintenance uses sensor data and machine learning to continuously monitor equipment health. By identifying early warning signs of wear or malfunction, teams can schedule maintenance before failures occur, minimizing unplanned downtime and lowering repair costs. This proactive approach increases asset uptime, extends machine life, and supports continuous production quality and throughput.

What data integration challenges do manufacturers face with Industrial IoT solutions, and how can they be addressed?

Manufacturers often struggle with siloed systems, incompatible software, and fragmented data sources, hindering real-time insights from IIoT devices. Integrating sensor streams with enterprise analytics requires scalable event ingestion, unified data models, and secure API architectures. Leveraging platforms like AWS IoT Events, Azure Event Hubs, and enterprise analytics tools ensures smooth data flow, real-time visibility, and decision intelligence across operations.

Why is SEIDOR Opentrends a strategic partner for connected devices and Industrial IoT initiatives?

SEIDOR Opentrends brings deep expertise in connected devices, IoT, AI integration, and cloud-native architectures, with over 30 enterprise IoT ecosystems in production. Their multidisciplinary teams design secure, scalable, and human-centered solutions that turn device data into actionable insights. By combining advanced analytics, UX-led dashboards, and robust architectures, SEIDOR Opentrends helps organizations transform isolated systems into intelligent, integrated environments that evolve with business needs.